Flake Epoxy Flooring Seattle

Transform your Seattle home or business with one of the most popular materials in today’s day and age – flake epoxy flooring. Consisting of a blend of polymers and pigments poured onto a concrete surface, flake epoxy, also known as “chip” epoxy, is an appealing and durable flooring option available in a variety of colors and textures. Get in touch with Epoxy Northwest today at (425) 890-4327 to learn more about this fantastic flooring alternative and how epoxy flake flooring could be the perfect solution for your space!

Understanding Flake Epoxy Flooring

Flake epoxy flooring is a contemporary flooring option consisting of polymer resins mixed with hardening agents. This material acts as a plastic coating applied over concrete floors, enhancing durability while providing a beautiful aesthetic appeal that looks significantly more modern than traditional garage floor paints or concrete.

Epoxy flooring is commonly used in basements, garages, home gyms, and workspaces because of its strength and exceptional durability under high-traffic conditions. However, its applications extend far beyond the home –hospital floors, retail stores, commercial kitchens, showrooms, warehouses, machine shops, factories, and any other highly trafficked zones may benefit from epoxy flake flooring.

Advantages Of Using Flake Epoxy Flooring

As stated above, flake epoxy has risen in popularity primarily due to its aesthetic appeal along with its durability, ease of maintenance, and stain protection. Revamp your space with flake epoxy flooring and reap numerous benefits, including:

Durability

The strength of flake epoxy flooring helps make it ideal for heavily trafficked spaces. The potent polymer resins create a durable surface that prevents stains, scratches, cracks, and fading. Whether you are thinking about installing flake epoxy in your home garage, bustling office space, or crowded retail shop, epoxy flake flooring is tough enough for the job.

Easy Upkeep

Cleaning and upkeeping flake epoxy floors is a breeze. Epoxy floors have a smooth surface that makes sweeping or mopping a simple task, while spills can also be wiped clean easily. Their texture also creates a complex dimension that hides dirt and debris in between cleanings - a win win!

Aesthetic Appeal

Flake epoxy flooring comes in an extensive range of colors and styles that allow for infinite design opportunities. Whether your preference leans towards classic gray flake or more eye-catching color combinations, such as red or blue, there’s sure to be a flake epoxy floor option that caters to your aesthetic preferences whilst enhancing the visual appeal of your space.

Chemical Resistance

Flake epoxy flooring is perfectly suited for commercial or industrial environments prone to spillage as it boasts chemical and stain-resistant properties. This material is also extremely resistant to fading and oxidation.

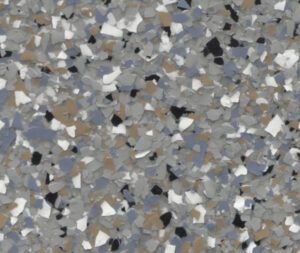

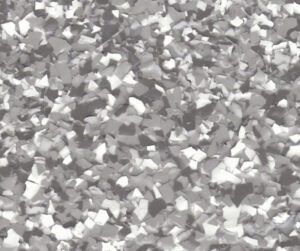

Epoxy Flake Flooring Colors

With epoxy flake flooring, you have an extensive array of options. Amongst the popular kinds of flake epoxy flooring are monochromatic flakes, metallic flakes, and custom flakes featuring unique colors. Monochromatic flakes provide a sleek and contemporary aesthetic, while metallic flakes impart a hint of glitz and gleam. Browse our epoxy flake flooring colors we offer here at Epoxy Northwest below:

Signature Collection

Custom Colors

The Process Of Installing Flake Epoxy Floors

At Epoxy Northwest, our flake epoxy flooring installation process involves precise steps for a perfect finished project. Here’s a step-by-step breakdown of how it all comes together:

Prepping the Floor

The process begins with grinding 1/32nd of an inch off the floor. This step ensures that the epoxy adheres properly to the concrete surface and removes any imperfections or coatings present. Etching should never be used for preparing the concrete, as it may leave behind residue and affect the adhesion of the epoxy.

Crack Repair

Before applying the epoxy primer, we repair any cracks or imperfections in the concrete using an epoxy-based crack repair material that ensures a smooth surface.

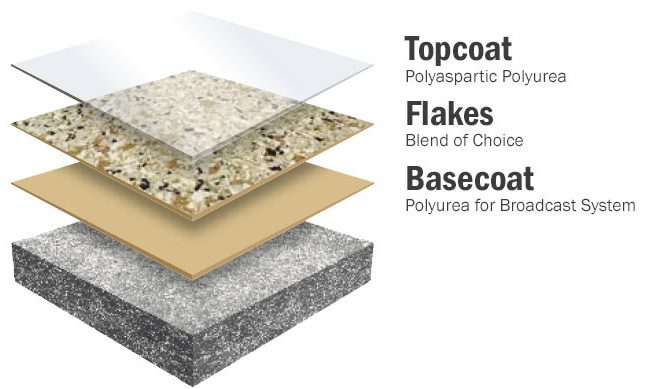

Epoxy Water Vapor Barrier

To prime the concrete, we apply an Epoxy Water Vapor Barrier, which prevents moisture from seeping through and affecting the epoxy coating. It also acts as a bonding agent between the concrete and the epoxy.

Add Flakes

Next, we add the flakes of paint into the epoxy primer. These chips not only add a decorative element but also provide texture and grip to the surface while hiding imperfections and creating a seamless finish.

Top Coat

For the final step, we apply the top coat. The top coat is typically made of the highest quality Polyaspartics, which provide enhanced durability and protection against stains, chemicals, and UV damage. This top coat ensures the flake epoxy flooring looks beautiful and lasts for years.

Flake Epoxy Flooring Installers in Seattle

Upgrade to Flake Epoxy Flooring Today

Make the smart choice and upgrade to beautiful and durable flake epoxy flooring today! Whether you’re a homeowner in Seattle looking to renovate your basement or a business owner in need of a high-performance flooring solution, flake epoxy flooring is the perfect material. Get started by contacting Epoxy Northwest at (425)-890-4327 today.